Table Of Content

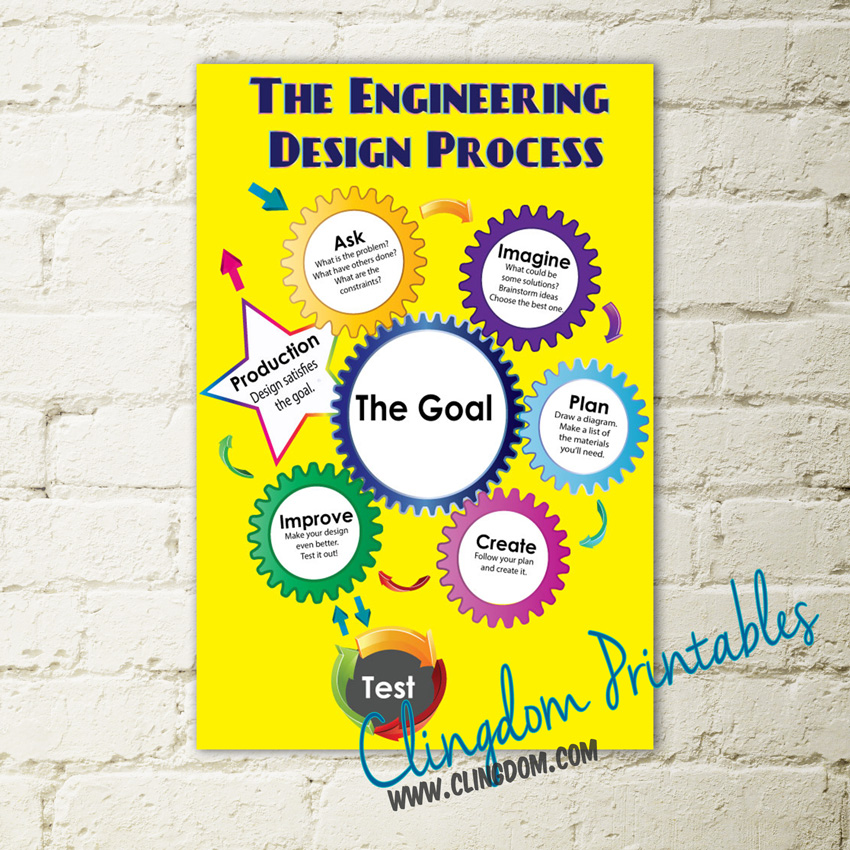

Once you have all the information to hand, brainstorm a list of possible solutions. Multiple experts working toward a common goal can help you eliminate possible issues or shortfalls before a product is in the hands of customers. For example, a person goes to the local hardware store and asks for a drill for their home improvement project. In select learning programs, you can apply for financial aid or a scholarship if you can’t afford the enrollment fee. If fin aid or scholarship is available for your learning program selection, you’ll find a link to apply on the description page. When you purchase a Certificate you get access to all course materials, including graded assignments.

Frequently asked questions

Additionally, within this logical progression of steps, teachers can use what they know to teach STEM as they evaluate, learn, and master the resources available to them. By the end of the time-consuming prototype development and testing phase, the design is completely ready to go into batch production. Criteria and constraints are used to evaluate the quality of a design. Constraints describe conditions that must be met by the design and design process; a design must meet all constraints.

Review Questions

Their role as the expert boatbuilder specializing in aluminum watercrafts does not change the fact that step-by-step, concise informational/explanatory writing is required. It’s important to caution students that they should try to meet all of the design specifications—both those already established, and those that they create. However, they should also be reassured that if their design does not meet the established criteria for success, it’s not equivalent to a failing grade. In substep, D.2 – Evaluate the Results, students should explore the degree to which the design specifications were achieved. For example, with paper airplanes that need to fly far and straight, students can set up launchers at their tables or desks.

Materials List

Look over parts C.1.2 and C.1.3 of the Water Tank Engineering MYP lesson for ideas about documenting the building and testing plans. If the prototype is a cooperative project and student roles for testing need to be determined, students can write a testing plan as well. Quick pencil sketches of the watercrafts, then a gallery walk to share among classmates, is one way to grow ideas. Look over part B.1.1 in the MYP unit, Water Tank Engineering with Newspaper, for an example of brainstorming.

Engineering designs optimize for manufacturing feasibility and efficiency, minimize potential production challenges, and reduce lead times and costs. As a professional rapid manufacturing company, WayKen enhances the engineering design process by offering advanced production and manufacturing solutions to meet specific needs. With WayKen’s support, you can identify and address potential production issues early on, ensuring smoother transitions from design to production. The engineering design process is arguably the cornerstone of product development projects, be it small-scale customized products or hi-tech industrial equipment. It provides engineers with clear guidelines on how to plan projects and track their progress. In this article, we will discuss the engineering design cycle and process in detail.

C.1 – Plan the Build (and Maybe the Test)

This visual evidence documents accurately how the watercraft was made. If you want the test data to be as accurate as possible, presenting a non-negotiable testing plan might be the way to go–or at least specify a couple of critical steps. For example, pennies should be placed carefully, one by one, in the watercraft prototype, not dropped. For virtual students, testing physical designs as a group is not possible.

Additive Manufacturing: “Those who wait will miss the boat” - Siemens

Additive Manufacturing: “Those who wait will miss the boat”.

Posted: Thu, 08 Nov 2018 08:00:00 GMT [source]

Plus, if you’re conducting the test in a face-to-face context, it keeps observers focused and helps with classroom management. Failure when testing the paper water tanks was more nuanced than with the aluminum watercraft prototypes. The complete sinking of the aluminum watercraft equates to failure and ends the test. At the end of the next step, B- Developing Ideas, students will create the official sketches of their best watercraft ideas.

With this information, you can evaluate the trade-space your question falls under. You can see what has already been explored and where there are gaps for you to contribute new ideas. This can be in the form of a report, presentation, display board, or a combination of methods. Thorough documentation allows your finished product to be manufactured to the required quality standards. Each prototype will need testing, re-evaluation and improvement.

Then, in a hypothetical engineering scenario, they use common classroom supplies to design and build their own structural, transport and defense protein models to he... Students further their understanding of the engineering design process while combining mechanical engineering and bioengineering to create an automated medical device. Students design, build and test looping model roller coasters using foam pipe insulation tubing. They learn about potential and kinetic energy as they test and evaluate designs, addressing the task as if they are engineers. Working individually or in pairs, students compete to design, create, test and redesign free-standing, weight-bearing towers using Kapla® wooden blocks.

This is an intensive brainstorming stage where the design team pitches ideas for different design concepts. The focus is on creativity and problem-solving, where team members are encouraged to find all possible solutions to the problem at hand. Similar to real-world engineering, our project requires strong teamwork, research, design, building, testing and communication. You will have a chance to get creative and work hands-on with a variety of materials. However, before we can dive into the design/build/test stages, let's take a start at the beginning and gather some information about the project. The engineering design process is designed to be versatile to meet the requirements of different types of projects.

The advantage of using a spiral design process is that the end design is often much better than the initial design. Prototypes are tested to see whether the design meets all constraints and performs acceptably relative to the criteria. Sometimes, poor design decisions made early in the process will make it impossible to develop a design that successfully meets customers' needs. When worksheets are completed, lead a class discussion to explore students' responses to the worksheet questions. Ask each team to present their answers to one section of the worksheet.

Draw up a product design to solve the problem while addressing constraints and potential issues that may arise during the build. Once you’ve developed your prototype, make sure to create documentation. Even though this is often presented as a less exciting part of the process, it’s very helpful for you, your co-developers, and others who might want to use it. The knowledge might be fresh in your mind now, but it won’t always be. Say you turn your attention to another project and come back to your prototype a year later.

No comments:

Post a Comment